When our air freight team in Frankfurt receives an urgent order that requires ad-hoc delivery of goods, they respond right away. That is nothing new.

However, just recently, our air freight specialists created a logistics solution for an oog piece: a machinery spare part weighing approximately 12 tons and having a diameter of more than four meters had to be shipped from the factory in Germany to Minnesota, USA, within a very short time frame. The customer: a renowned manufacturer of industrial equipment for the mining industry. The solution: chartering an Antonov 124. The particular: from receiving an inquiry to the actual delivery only 2.5 working days passed.

When industrial machinery parts need to be shipped via air freight, time often plays a critical role. “Often, such shipments are spare parts that cannot be waited for a longtime, as to avoid delays in on-going production processes. Shipping via ocean freight is not an option then”, our air freight specialists in Frankfurt/Main say. Same applied to the oog machinery spare part. Between accepting the inquiry on a Friday afternoon and the actual delivery on the following Tuesday only 2.5 working days passed.

Always keeping an eye on time, we realized detailed transport concepts for the pre- and main carriage.

However, it was not the critical time factor that required special know-how and out-of-the-box-thinking – ad-hoc solutions are part of the daily business of our air freight team in Frankfurt. It was the dimensions of the machinery part. “For the oog piece with a diameter of more than four meters, no standard logistics solutions came into play. So, we had to develop special logistics solutions for the pre- and main carriage – always keeping an eye on time”, our air freight experts explain.

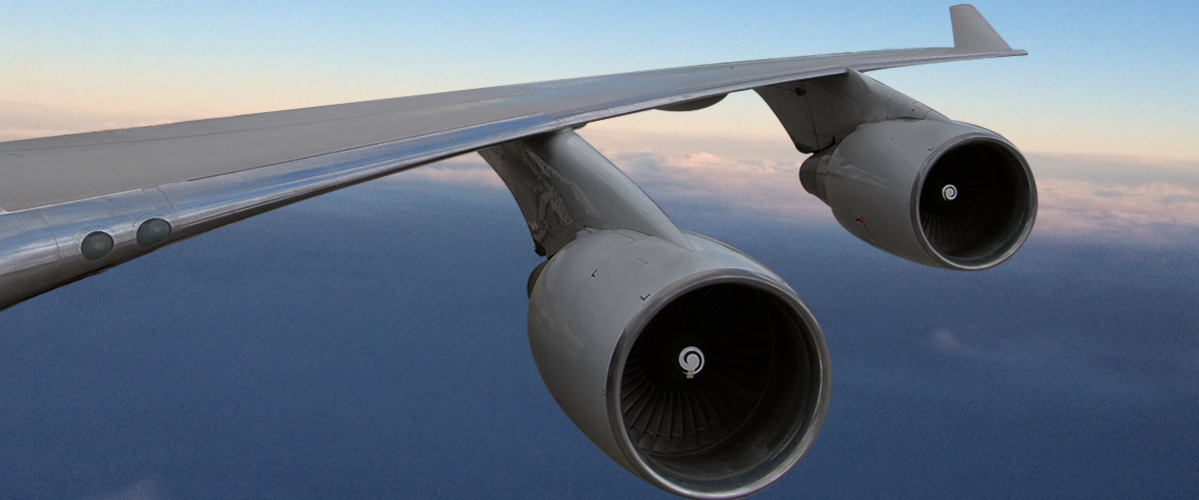

“’Regular cargo aircrafts’, such as a Boeing 747 and 777 were not considered for the main carriage, because of the dimensions of the spare part. Depending on the type of aircraft, the cargo doors have a maximum width of up to 3.70 m and a maximum height of up to 3.15 m”, our air freight specialists explain. The solution: chartering an Antonov 124.

Change of locations for short road haulage

“We knew that Antonov aircrafts are often ‘parked’ and maintained at Leipzig Airport (Eastern Germany). So, we immediately asked for availability of an aircraft, determined the best located airport, and ordered the aircraft there – to a Western European airport. “The ‘change of location’ was necessary to keep the road haulage of the cargo as short as possible”, our colleagues say.

Parallel to the transport concept for the main carriage, our air freight team in Frankfurt also took care of the pre-carriage concept. In any case, it was important to avoid waiting times for transport permits. There are maximum permitted dimensions for road haulage that need to be complied with. “Anything beyond that requires a permit”, says our air freight team. However, our team managed to conform to the maximum allowed dimensions.

With a special logistics solution, we managed to comply with the maximum allowed dimensions for road haulage.

How? To minimize the perimeter, the machinery part was unpacked and fixed in a tilted position on the trailer. Already on Saturday, the machinery part was on the road for its first transport section. On Monday the spare part was finally delivered at the airport. “Because we wanted to avoid the Monday morning rush hour best possible, we divided the road haulage into two sections”, our air freight specialist explains.

On Tuesday, after the usual security checks, the urgent shipment was loaded into the Antonov aircraft with the help of the on-board crane. With a flight time of approximately 9 1/4 hours, the plane landed on the same day at the destination port – only 2.5 working days after receiving the inquiry from the customer.

"It's always exciting and challenging making such an urgent delivery of oog cargo possible within such a short time frame," our Karl Gross air freight specialists conclude.